Best Tool Steels Property For Shear Blades

Tool steel is a material capable of withstanding high pressures and possesses great hardness. The main condition imposed by the tool steels that you keep the edge for a long time. Unlike machine parts (shafts, cams, etc.) on the cutting tool works only wear a very narrow strip of metal that undergoes considerable pressures. For this metal strip resistance to wear must have a high hardness, usually greater than HRC 60.

If intangible soft (working Wood, Plastics, Metals non-ferrous) or whether steel or cast iron (Metals) small cutting speeds and chip has a little section in unit time is spent little energy in the process of court. If the work is done at high speed cutting and hard metals working section has large chip in the unit of time is spent lots of energy.

The mechanical energy is transformed during the process of cutting energy and heat the edge of the tool is very hot (up to catch red) when the cutting conditions are harsh. This tool is the main condition imposed is that it retains its strength over a long period of warming.

Categories:

For the various different types of tool steels are used, these are divided into the following categories:

- Low hardenability (mainly carbon)

- High hardenability (alloy)

- For matrices

- Rapid

Low hardenability Steel Tool:

This group includes all steels Carbon and tool steels with low content of alloying elements that do not differ much for your hardenability of carbon steels. Collect these steels in a wider group its proprietary technology is low hardenability. Low hardenability steels for tools carbon content is 0.6 to 1.15%.

Steel high hardenability Tool:

This group includes alloy steels containing elements in quantities of 1-3% and, therefore, has greater hardenability. The tools made of these steels are quenched in oil and the temple is staggered in salt.

Steels for matrices:

For metal working tools for pressing dies, punches, rolls, cylinders, etc. are used. That deforms the metal. Loa metals used for tools of this type are called steels matrices.

The steel matrices are divided into two groups:

- Cold metal to deform

- Hot deforming metal

This group includes steels that are manufactured for cutting tools working at high speeds. Speed steel must have firstly a hot hardness and stability to red.

Source:

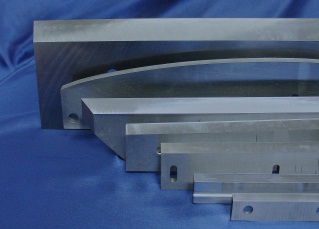

Ground-Flat-Stock.co.uk – the one and only place to buy tool steel for shear blades and other cutting blades.

Contact Us!

Sheffield Gauge Plate Limited

Bastock Road

Hillsborough

Sheffield

South Yorkshire S6 2AE

Telephone: +44 114 2335291

Fax: +44 114 2347833